17

METTLER TOLEDO

Industrial Catalog 2015

Focused Solutions

Formulation systems have to cover

a broad spectrum of requirements.

They ensure traceability and regula-

tory compliance without significantly

increasing operator workload.

Scalability

Customers have varying needs and

applications, which can be met by

a variety of products ranging from

standalone systems up to compre-

hensive, scalable and integrated

networked solutions. Formulation

systems must fit into the customer's

setup with minimal adaptation of

existing processes.

METTLER TOLEDO offers solutions

for simple formulation tasks and

scalable configurations for integra-

tion into host ERP systems.

This extensive portfolio allows the

company to offer full customization.

Getting the mixture right

Simple and consistent prompts

via the user interface ensure reli-

able weighing. Functions like batch

identification, transfer of weight

values within tolerance, ingredi-

ent overweight correction options

and automatic calculation of active

ingredients are important factors in

achieving dependability and largely

Reliable Production

Ensured by Modern Formulation Systems

avoiding incorrect mixtures and

waste of expensive raw materials.

METTLER TOLEDO products support

your efforts to achieve high formu-

lation quality with excellent weigh-

ing equipment (such as balances,

industrial terminals, label printers

and barcode readers).

Traceability

Seamless traceability in relating an

order back to its production batch-

es, raw materials or balances in

which the batch has been produced

is paramount in sectors, including

the pharma or food industry (EU

178/2002).

21 CFR Part 11/111 conformity

Compliance with legislation and

regulations (such as those of the

FDA, especially in 21 CFR Part

11/111 relating to the pharmaceuti-

cal sector) plays a central role in

formulation.

FormWeigh.Net

®

from METTLER

TOLEDO meets regulatory and

traceability requirements.

Read more about FormWeigh.Net

®

on page 44–45.

www.mt.com/formweighnet

www.mt.com/formulation

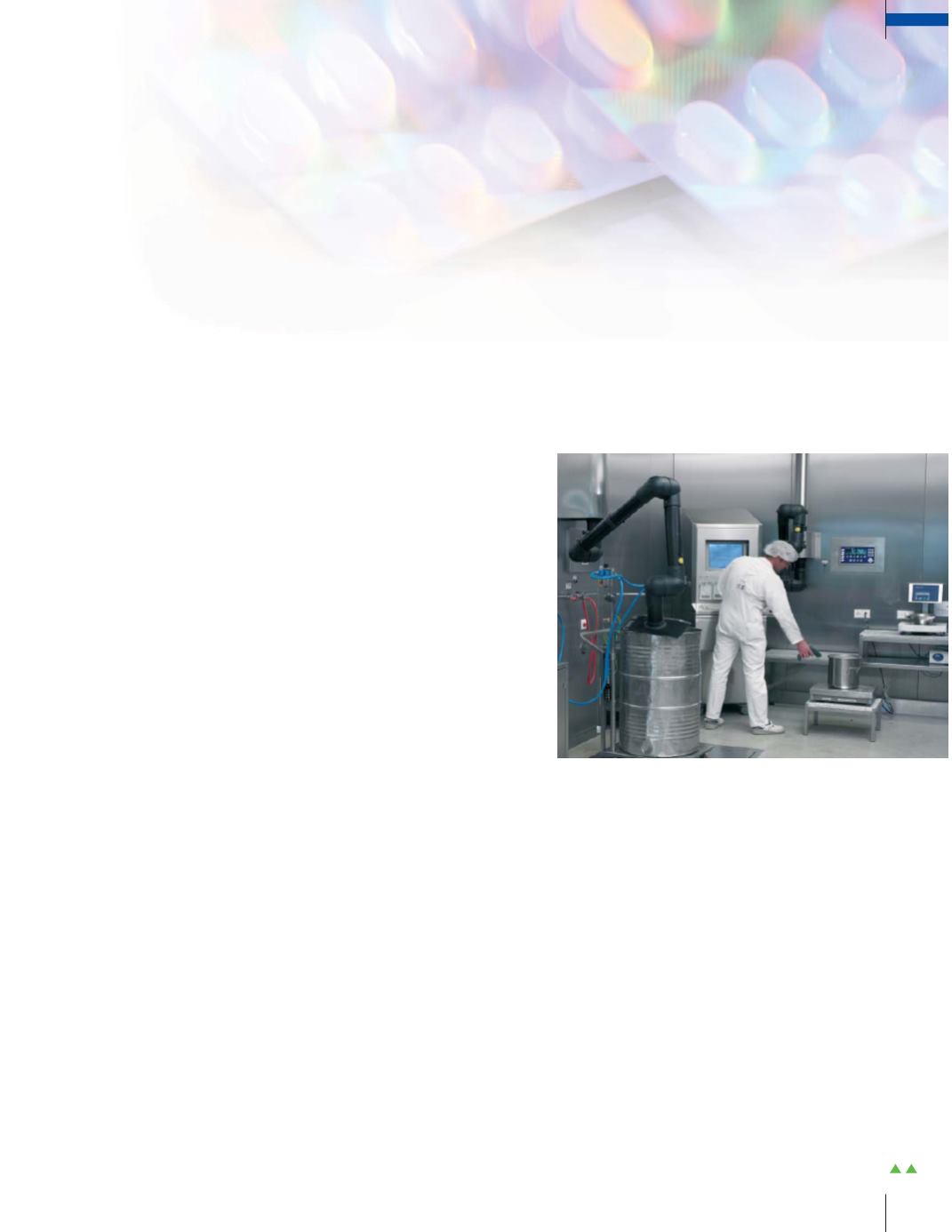

Manual formulation remains very important even on highly automated cutting-edge

production lines. Computer-based formulation systems allow faster production of

continuously improved quality and lower rejection rates. The emphasis is on traceability

and regulatory compliance.