60

METTLER TOLEDO

Industrial Catalog 2015

Industrial Terminals

• Tracking and traceability of material, lot and batch

• Manual and fully-automatic batching

• Eliminates rework caused by incorrect or misweighed materials

• Uses lot number to find a bad lots or recalled batches at the touch of a button

• Assured conformity to food safety regulations

Fully-Integrated

Batch Controller

The system features unmatched

flexibility, with advanced batching-

control technology that adheres to

the ISA SP-88 Batch standard.

• Works as a standalone terminal

for single or multi-scale applica-

tions

• Optimizes your batch process

with consistent, accurate mate-

rial transfers

• Minimizes material waste,

improves batch quality and

yields increased profits

• Meets legal metrology and

safety standards in most

world markets; multilingual

firmware adaptable to local

requirements

• Features intelligent recovery

from power loss to prevent

waste of valuable material

• Has print capability for end-of-

batch summary and custom

print messages

Markets

• Food & Beverage

• Glass

• Chemical

• Pharmaceutical

• Aggregates

• Plastics

• Others

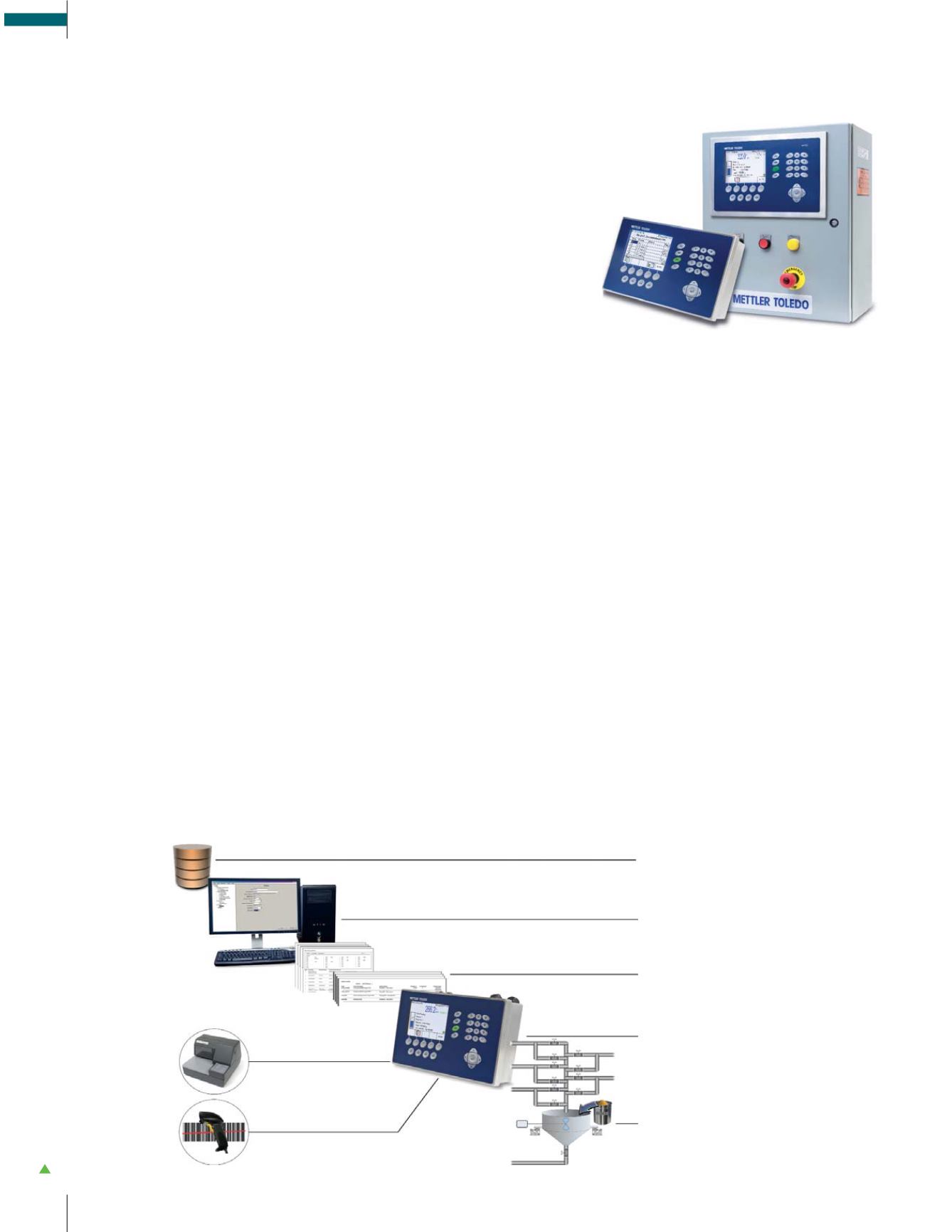

Measurement Devices

• Scales and Load-Cell Systems

• Flow Meters

Raw Materials

• Granules

• Powders

• Liquids

• Slurries

Recipes

Orders

Printer

Terminal prints batch data

automatically and on demand

Barcode Scanner

Input devices simplify material

lot and batch tracking

Customer Database

Stores process data and system

configuration information.

IND780batch PC Configuration Tool

Configures equipment, creates and manages

recipes and orders, generates track and trace

data and reports.

Configuration tool downloads recipes and

orders to one or more controllers.

IND780batch terminals

Control automatic and manual batching

processes.

Batching System

Carries out manufacturing process.

www.mt.com/IND780batch