129

METTLER TOLEDO

Industrial Catalog 2015

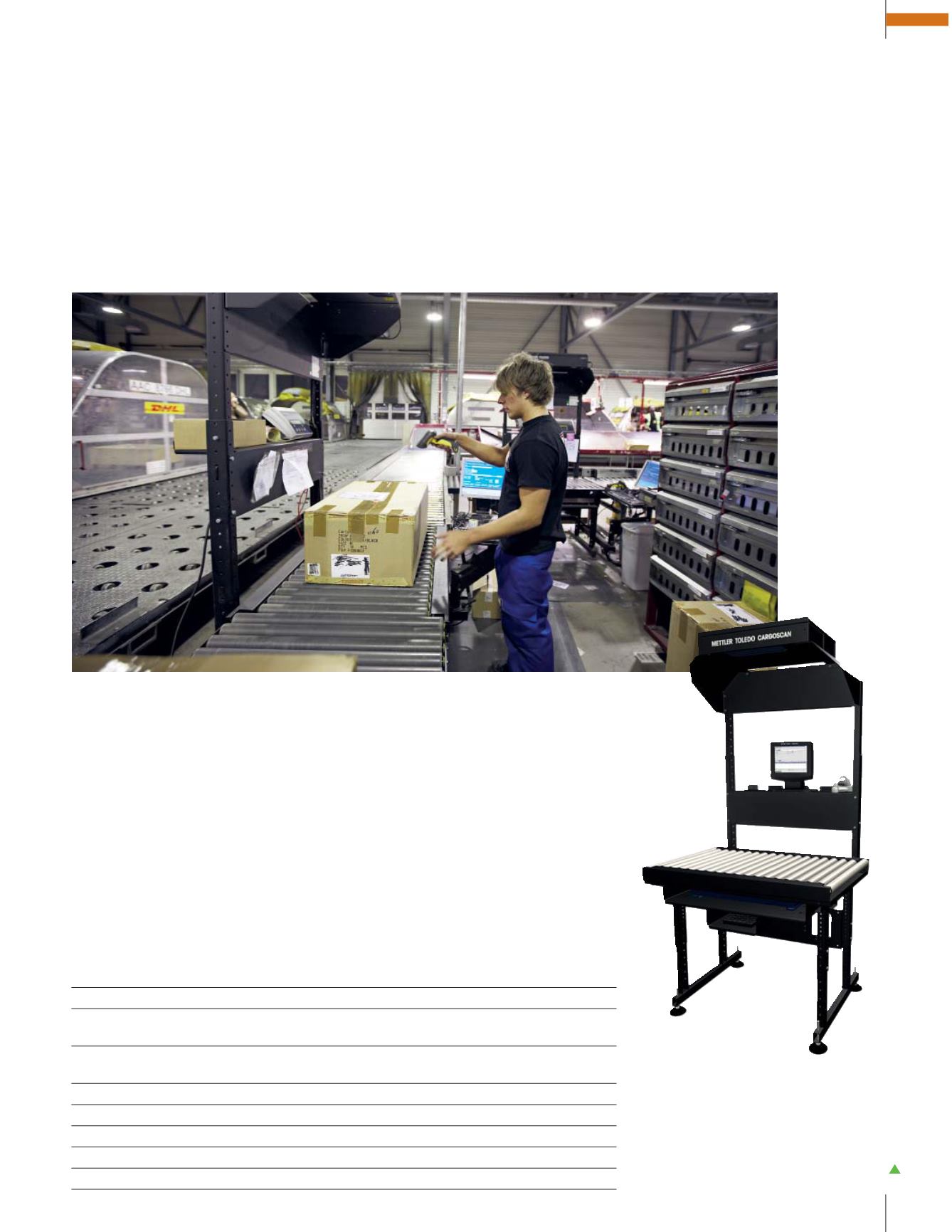

Dimensioning, Weighing and ID

www.mt.com/CSN810

Our static systems are designed

to dimension, weigh and identify

stationary objects. Place the object

under the dimensioner manually

or with a forklift truck and scan

the bar code. In seconds the data

is captured and the object can be

removed. Regardless of the size of

your operation, we have an easy-

to-use system to help you automate

From Parcels to Pallets

Static Dimensioning, Weighing and ID

your data collection. Operators can

increase productivity from the day

the system is installed.

Automate data collection

and eliminate:

• Data inaccuracy

• Human error

• Re-entering of data

• Paperwork

Model

CSN810 TableTop™

Dimensioner accuracy*

± 5 mm

Maximum size (L xWxH)

Flat table: 1,150×750×700 mm

Roller table: 1,000×600×840 mm

Minimum size (L xWxH)

Flat table: 50×50×50 mm

Roller table: 100×50×50 mm

Throughput

Approx. 400 per hour (dependent on operation)

Shape

Rectangulars

Weight

Minimum: 0.9 lb; Maximum: 330 lb (Flat), 132 lb (Roller)

Scale resolution

± 0.04 lb

Barcode reading

Wireless handheld; Laser based (1D codes)