138

METTLER TOLEDO

Industrial Catalog 2015

Increase Production Line Efficiency

And Protect Your Brand Reputation

In-line checkweighing helps prevent underweight product from being shipped while

minimizing the risk of costly overfill. Hi-Speed's comprehensive range of dynamic

weighing solutions helps to deliver productivity and profitability for manufacturers in

industries including food and beverage, chemical, pharmaceutical and others.

Solid and heavy-duty construction

provides a rugged, stable foundation

for precise and consistent check-

weighing. Programmed speeds can

be stored with product set-ups for

fast and easy product changeover.

Control options such as statistics,

filler feedback control and compre-

hensive connectivity packages help

our checkweighers fit seamlessly

into any production line.

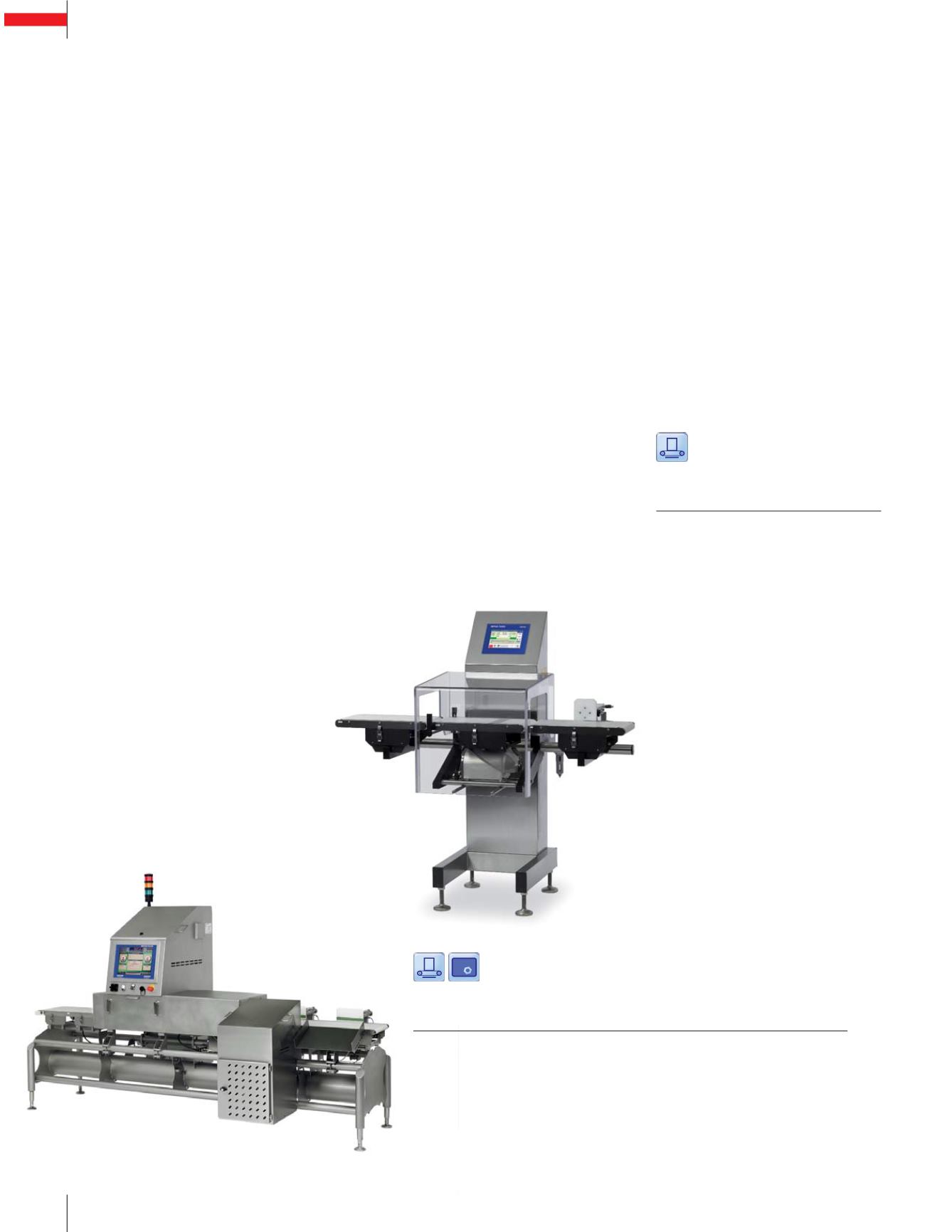

Economic & Flexible

Hi-Speed XE Checkweighers

State-of-the-art, dynamic weighing technol-

ogy at an economical cost. The standard de-

sign of the XE2 and XE3 models comprises

a device for height adjustment as well as

reversible transport direction.

All XE models have variable speed control

and allow for upgrading. A wide range of

options allows them to closely meet a range

of user requirements. The modular concept

makes the XE models very service-friendly.

They require little maintenance.

Hi-Speed XE2 Checkweigher

Weighing range: up to 1.32 lb

Throughput: up to 200 pcs/min.

Hi-Speed XE3 Checkweigher

Weighing range: up to 13.2 lb

Throughput: up to 200 pcs/min.

Hi-Speed XE40 Checkweigher

Weighing range: up to 88 lb

Throughput: up to 100 pcs/min.

Hi-Speed XE100 Checkweigher

Weighing range: up to 265 lb

Throughput: up to 80 pcs/min.

Precision Weighing and Foreign-Body Detection

Hi-Speed XS3 AdvanCheK

This unit combines true weight measurement with the world's best sensitivity X-ray

inspection. The X-ray CombiWeigher "XS3 AdvanCheK" not only offers highly accurate

weighing results but also simultaneously checks your products for foreign bodies,

protecting not only consumers but also the good reputation of your brand. The x-ray

system can detect high density contaminants such as metal, glass and stone. Mini-

mum training is required to set up menus, thanks to an "auto set-up" software wizard

that ensures minimum downtime. The X-ray CombiWeigher from METTLER TOLEDO is

a compact and cost effective solution, ideal for use in the food industry.

Product Inspection