144

METTLER TOLEDO

Industrial Catalog 2015

Brand Protection

at the Touch of a Button

METTLER TOLEDO Safeline X-ray Inspection offers a range of X-ray systems for the inspec-

tion of packaged and unpacked products in the food and pharmaceutical industries. Our

X-ray technology offers exceptional contamination detection, locating foreign body con-

taminants such as glass, metal, stone, calcified bone and high-density plastics, even in

products packaged in foil or metallized film. In addition, X-ray systems can simultaneously

perform a wide-range of in-line quality checks including:

•

Measuring Mass

•

Component Counting

•

Identifying Missing or Broken Products

•

Monitoring Fill Levels

•

Inspecting Seal Integrity

•

Checking for Damaged Packaging

Latest X-ray Technology

Combining new technology, an ergonomic

design, improved user experience and

sustainability credentials, Safeline X-ray’s

revolutionary new x-ray systems are truly

market-facing and encapsulate the most ad-

vanced developments in product inspection

capability.

Advanced X-ray Systems

A choice of innovative detector diodes

(0.8 mm or 0.4 mm),a 20-Watt X-ray gen-

erator option and detector width options en-

able systems to be customzed to suit food

and pharmaceutical manufacturers’ individu-

al packaged application requirements, pro-

viding a future-proof investment, even if line

changes are required after the initial

installation.

Outstanding Detection Sensitivity

Designed in collaboration with custom-

ers, the next generation range is built upon

manufacturers’ needs and incorporates a

host of features and benefits. For example,

new detector technology, which is five times

more sensitive than a standard detector, en-

ables the next generation series of machines

to achieve very high levels of contamination

detection.

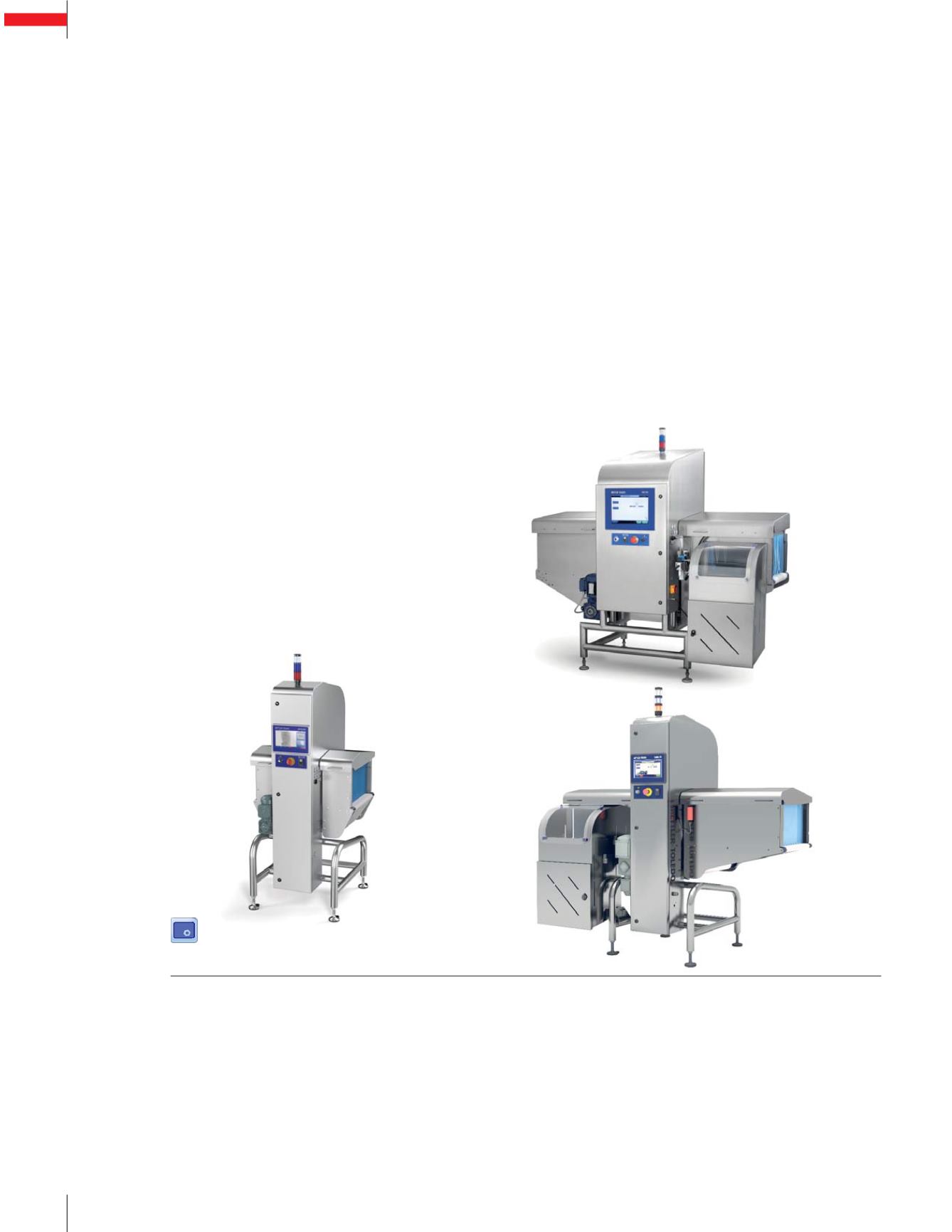

Next Generation X-ray Inspection Systems

Product Inspection

X36

X33 Short

X33 Long