150

METTLER TOLEDO

Industrial Catalog 2015

Product Inspection

Track & Trace and Quality Control

Pharmaceutical Packaging Industry

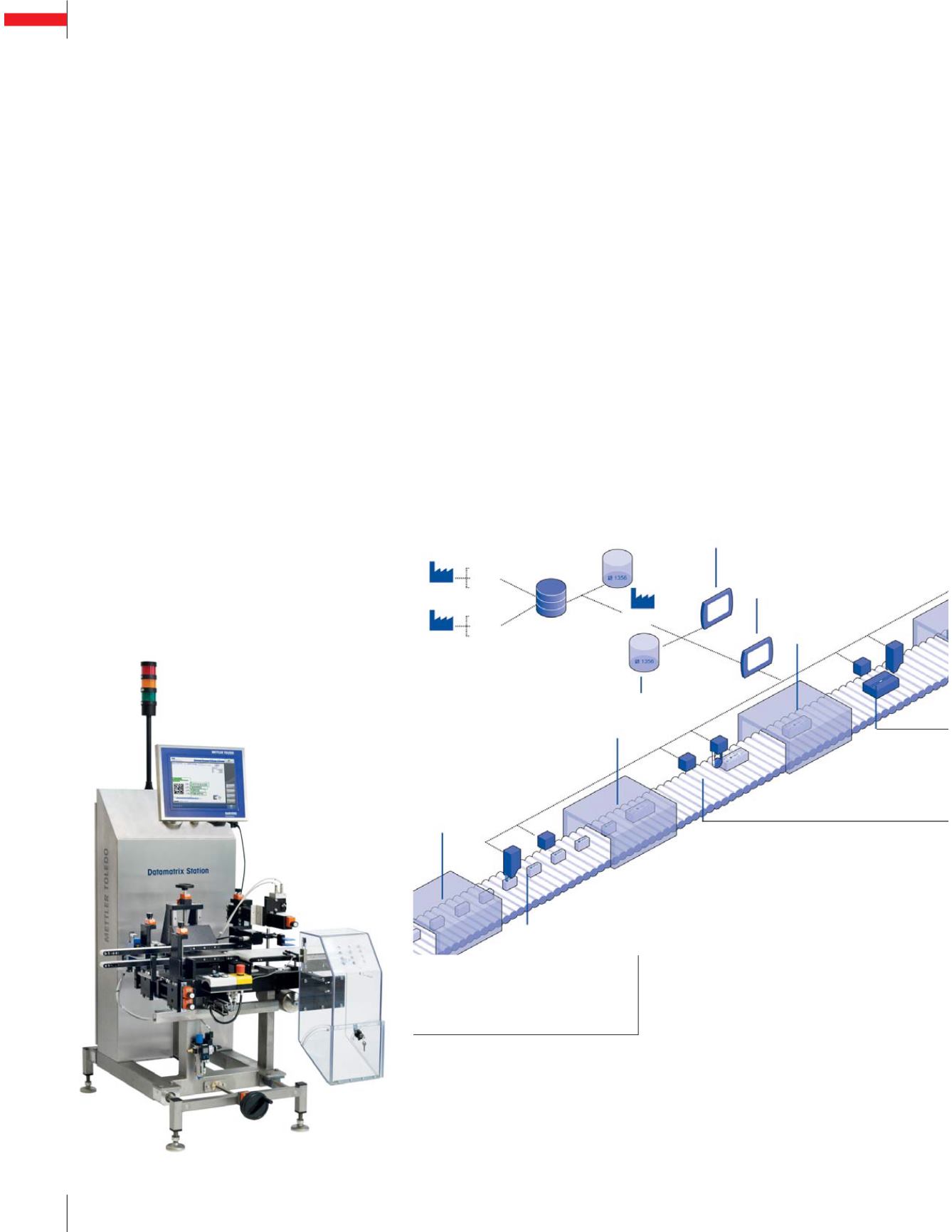

As a leading supplier of inline vision inspection solutions for the pharmaceutical in-

dustry, PCE provides comprehensive solutions for track and trace, serialization and

aggregation tasks and vision inspection equipment for packaging lines.

Manager and Pilot Site Manager)

ensures that printing, labeling and

verification of serialized data is

performed correctly. The PCE Pilot

Systems are available to mark

packs with individual serial num-

bers for full traceability of the

production or packaging process

and collect critical correspond-

ing process data. Solutions are

available for all packs including

single cartons to shipping cases

and ready-to-ship pallets. The PCE

management software (Pilot Line

software suite supports dedicated

devices as well as data exchange

to higher level IT systems.

Line 1

Line 2

Line 3

Line 1

Line 2

Line 3

Site 2

Cartoner

Bundle

Packer

Advanced

Bundle

Station

Datamatrix Station

or Bottle Serialization Station

Pilot

Database

Pilot

Site

Manager

Pilot

LIne

Manager

Shipping

Case

Packer

Shipping

Case

Packer

Site 3

Site 1

Datamatrix Station XMV

Safety Through Traceability

Marking, Verification and Sorting

A Fully Integrated Compact System

The Datamatrix Station XMV (DMS XMV)

minimizes the potential risks in pharmaceuti-

cal packaging through Track & Trace mea-

sures and adherence to guidelines. The DMS

XMV provides coding and serial number

coding to meet product traceability in com-

pliance with the EU Directive, USA ePedigree

and other worldwide track and trace require-

ments. The product codes and variable data

printed on the folding cartons are verified

via cameras for accuracy and quality. The

concurrent protocols meet GMP requirements

and quality assessments.

The DMS XMV system can be easily integrated

into new production lines or can be added to

upgrade existing lines providing a full range

of functions and user-friendly operation.