47

METTLER TOLEDO

Industrial Catalog 2015

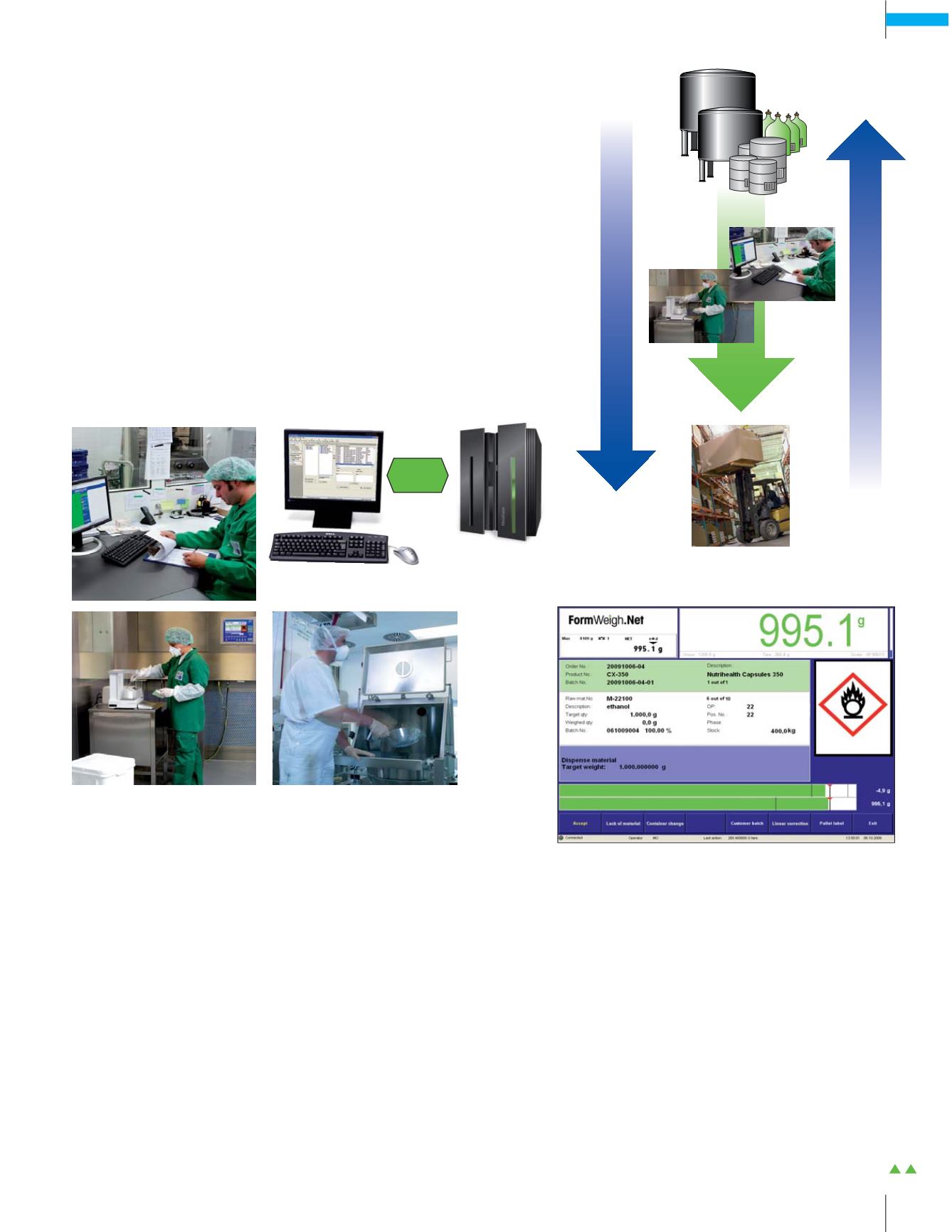

Dispensing & Formulation Software

FormWeigh.Net

®

offers:

• Graphical support to avoid incorrect mixtures

• Prevention of material waste

• Right mixture reliably documented

• 21 CFR Part 11/111 readiness

• Automatic calculation of active ingredients

• Acquisition and verification of batch information

• Clear, concise representation of the weighing

process

• Maximum process reliability

• Seamless traceability

• Validation support

• Automatic dosing

• Fast ROI (<12 months)

Weighing station 3

Master data management

Production

www.mt.com/formweighnet

www.mt.com/formulation

Standard Software for individual Needs

The modularity of FormWeigh.Net

®

allows optimization

your individual needs. The versatility of this METTLER

TOLEDO product, which is achieved through a combination

of a whole series of carefully matched function modules,

has major advantages in meeting stringent quality specifi-

cations in diverse production environments.

FormWeigh.Net

®

works alongside your processes and

documents them electronically on the centralized data-

base without compromising your flexibility.

FormWeigh.Net

®

allows you to take control of your work-

flows in such a way that you are always aware of which

orders are completed, in progress or awaiting processing.

Tracing

Tracking

ERP

Gateway

Integration into ERP Systems

The ERP gateway for FormWeigh.Net

®

allows simple,

automatic exchanging of data between FormWeigh.Net

®

and the production planning function of a host or

ERP system. The data can be exchanged via the SAP

interface or by means of ASCII file transfer or database

synchronization.

To eliminate potential entry mistakes, the order data,

parts lists and inventory information can be transferred

from the production planning system to the weigh-

ing system and the consumption data reported back.