49

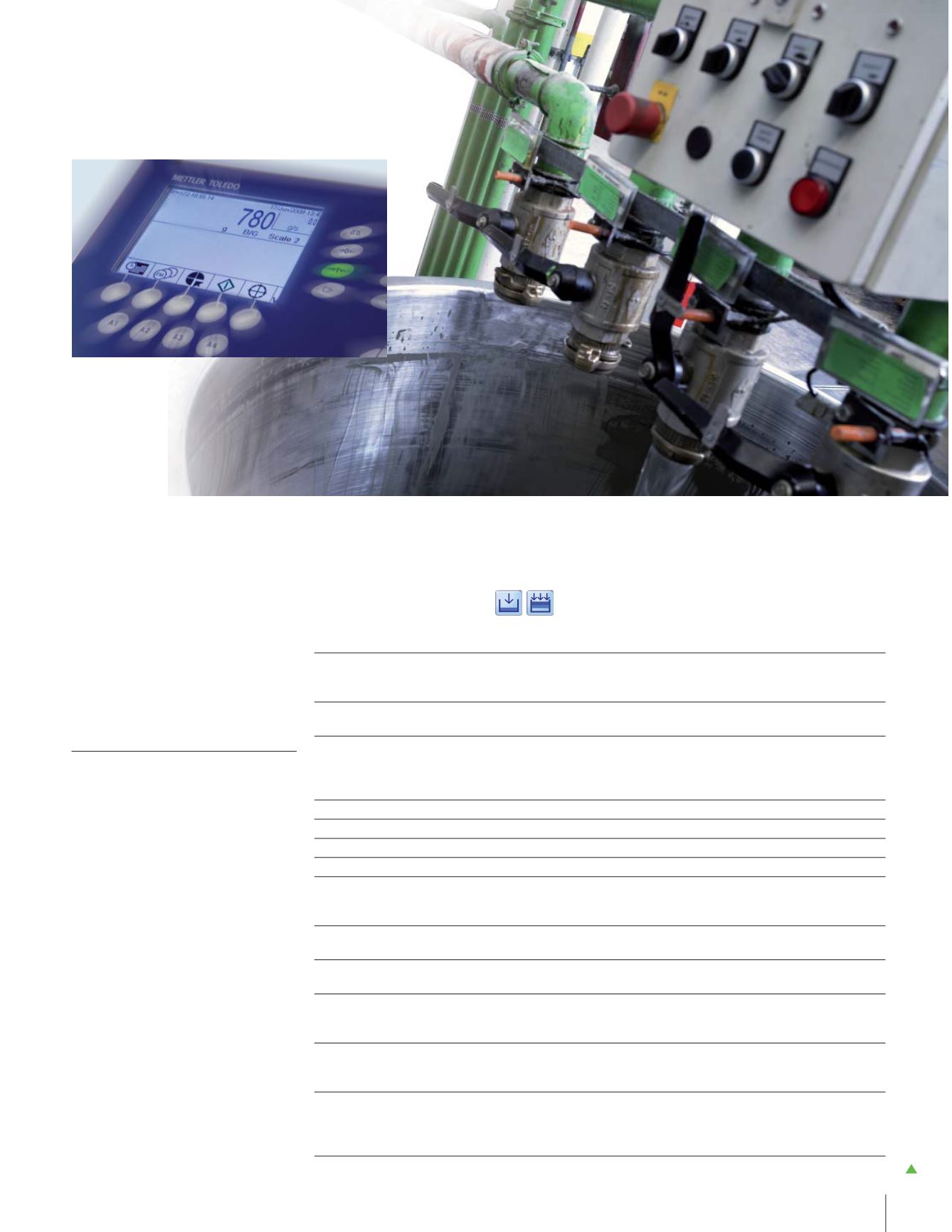

METTLER TOLEDO

Industrial Catalog 2015

Scales and Flow Meters

Process measurement tools include digital scales, analog scales, load cell

systems and flow meters, with concurrent monitoring and control

Multiple Measurement Tools

In each terminal, six option board slots support up to four analog scales,

per Q.i 780 Terminal

one multi-scale POWERCELL

®

PDX

®

interface, four IDNet/digiNet, twelve flow

meters, or a combination of these

Q.i 780 Clustering

Up to 198 total measurement tools in 20 Q.i 780 terminals,

clustered via Ethernet LAN

Fieldbus Communication

EtherNet/IP™, Profibus

®

DP and ControlNet™ for full fieldbus integration;

A-B RIO, DeviceNet™ and Modbus TCP for limited functionality; 2-channel,

4–20 mA analog output; two modes of host communication – classic

or enhanced, user-selectable and configurable

Predictive Adaptive Control

Up to 12 licenses per terminal, with up to 198 pooled licenses per cluster

Material Paths

Up to 999 per single terminal or cluster

Programming

TaskExpert™, standard with Q.iMPACT, supports function block programming

Display

TFT color graphical LCD display with backlight

Keypad

0–9 numeric keys, decimal point, clear, tare, print, zero, select scale, four

application-specific softkeys, five scale function softkeys, navigation arrow

keys, enter key

Target Cutoff

Analog load cell interface: 91.5 Hz; flow meter interface: >200 Hz; IDNet,

Comparison Rate

SICS, Modulo and POWERCELL

®

PDX

®

: Rate depends on cell type and model

Flow Meter Interface

Supports any flow meter with calibrated digital pulse output signal up to

24 V DC / 150 V AC and 1–50 KHz frequency range

Enclosure

Panel mount: 220×320×105 mm, stainless steel front panel, certified Type

4×/12 environmental rating; Harsh Environment/Desk/Wall mount:

200×299×245 mm, stainless steel, IP69k certified

Communication Ports

One RS232; one RS232/422/485; up to two additional RS232

port expansion cards; one TCP/IP 10/100 Base-T Ethernet;

USB master for external keyboard or external memory

Digital I/0 Options

Discrete I/0: Maximum of 40 inputs, 56 outputs; local (Relay or Solid State):

One or two modules, each with 4 inputs, external sink 5–30 V DC; 4 outputs

@ 30 V AC / V DC, 1 A max.; Remote: Up to 8 ARM100 I/0 modules,

4 in/6 out @ 60 V DC / 250 V AC, 1 A max.

More Time and Profit

in Production

Q.iMPACT

®

Material Transfer Controller

The world's most advanced material trans-

fer (feed) controller. Optimize your batch,

blending and filling-control operations. The

Q.iMPACT system leverages the flexibility,

features and functions of the IND780 termi-

nal. A robust, second-generation set of 21

embedded material feed functions enhances

and expands the terminal's capability. The

IND780 Q.I terminal is the ideal solution for

End Users, System Integrators and OEMs.

www.mt.com/qi