145

METTLER TOLEDO

Industrial Catalog 2015

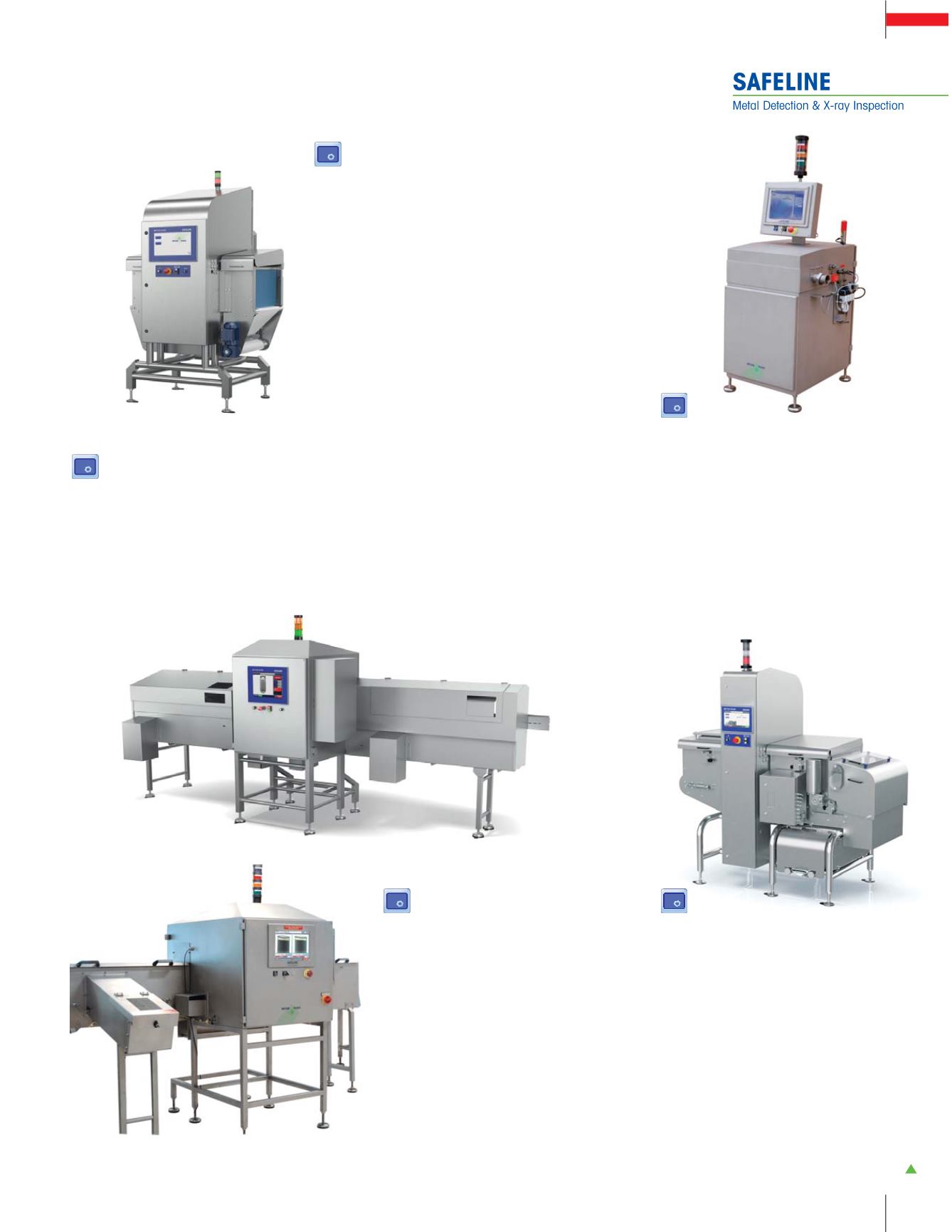

X-ray Inspection of Pumped Products

X-ray systems can be used for the inline in-

spection of pumped products, typically slur-

ries, semi-solids and fluids, before the final

packaging. X-ray systems for pumped prod-

ucts are used to inspect at the early stages

of production, to minimize waste and save

costs. Our Pipeline x-ray systems offer su-

perior product safety through contamination

detection in pumped food applications such

as condiments, meat, jams and ice cream.

X-ray Inspection of Packaged Products

X-ray inspection solutions offer complete

product integrity for packaged products on

single or multi-line applications, at high

production speeds. To ensure product qual-

ity and safety, our x-ray systems deliver

fast and reliable detection of contaminants

and are not affected by changes in product

temperature or moisture, thus ensuring

minimum false rejects. X-ray inspection

systems can simultaneously scan for miss-

ing or damaged items to confirm product

quality, ensure product freshness by check-

ing the seal integrity and measure gross or

zoned mass for portion control to protect

profitability.

www.mt.com/safeline-xray

X-ray Inspection of Glass Jars

Safeline X-ray’s glass inspection machines can detect glass, metals, mineral stone, high

density plastic and calcified bone, irrespective of their, shape, size or location within glass

jars and bottles. Glass in glass x-ray detection systems automatically detect and reject con-

taminated glass containers from your production line, at very high line speeds. Safeline X-

ray’s single and multi-beam x-ray inspection solutions can be used for a wide range of glass

containers, ensuring complete product safety.

X-ray Inspection of Metal Cans

Safeline X-ray’s range of X-ray inspection

systems for cans is capable of a wide range

of can in different shapes and sizes. Oper-

ating at high line speeds, metal cans are

able to run touching rim-to-rim, allowing

contamination detection at a rate of 1,500

cans per minute. Detecting contaminants in

the base or side walls of a can, is challeng-

ing. However, our split dual-beam system

overcomes this challenge with every can be-

ing imaged twice. Each image represents a

different viewing angle, increasing coverage

inside the container and the enhancing prob-

ability of detection.

X-ray Inspection of Bulk Products

Safeline X-ray’s bulk x-ray systems are

specifically designed for the detecting of

unwanted contaminants, regardless of their

shape, size or location within bulk-flow

(loose) products. Inspection before products

are packaged, or added as ingredients to

finished products, saves costs and reduces

waste before further product value is added.

Larger contaminants are removed before

they are broken down into smaller pieces,

which can potentially damage equipment.

Product safety is also enhanced.

Product Inspection

X33 Bulk

X36

InspireX R70

InspireX R50G

InspireX R50SB